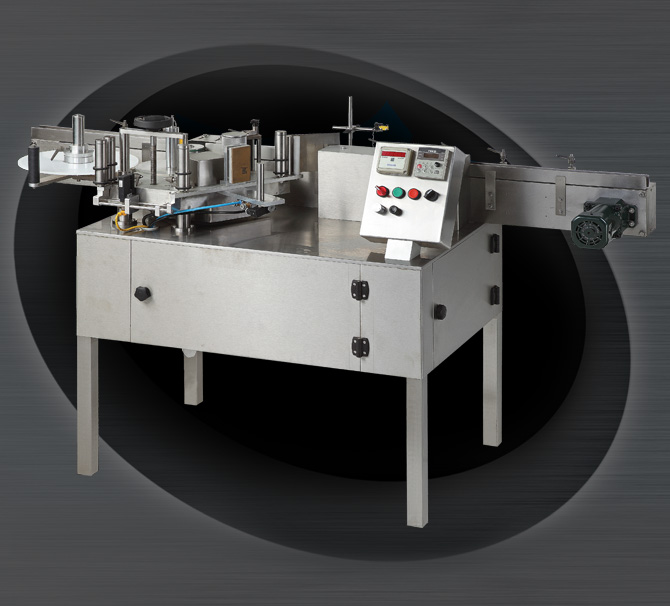

The Vertical Automatic High Speed Sticker Labelling Machine Model LABELSTIK-150, is one of the most user friendly. The Machine incorporates latest sophisticated Micro Processor Control Label Dispensing system with user friendly Sensing system for Label and Product. The machine is suitable for Labelling on Round Vials, small size of Bottles and other round objects. It is capable of Labelling up to 150 units per minute depending on product diameter and label size. Machine suitable for Vials and Small Sizes of Bottles from Glass, Plastic, PET, HDPE, PP etc.

The Automatic Models are equipped with “Roller Spacing Device” resulting in a simple no change parts system and eliminating the need of Feed-Worm or Star Wheel for uniform product separation.

The Sticker Labelling Machine LABELSTIK-150 has its own unique single point synchronised speed control system. The Inbuilt Automated Label Length detection systems eliminates any need for manually feeding and storing of Label Length data in memory and retrieving the same every time for change of Label Size & re-starting the machine. The System thus saves valuable time, avoiding machine-down time, and helps achieve higher production. Machine can be supplied with Optional Toughened (Tampered) Glass or Acrylic Safety Cabinet. Machines having required all basic features as a standard fitment to match the current market needs and also saves cost and time.

|